Liquid Rocket

Propulsion

Why Liquid Rocket Propulsion?

With current and near future technology, liquid propulsion has

several mission critical advantages over solid and hybrid

propulsion.

1. Specific impulse, Isp. Isp as high as a 455.

2. Low cost fuel and oxidizer. As low as $0.25 per pound.

3. Throttling and pulsing.

Wether you need the highest performance for your single

mission or the best cost effectiveness for a reusable

application, liquid propulsion technology has a proven track

record which may be your best solution. Examples of projects

which are well suited for liquid rocket propulsion are:

- launch vehicles,

- sounding rockets,

- positioning thrusters,

- "space tourism" rockets,

- lunar or mars "hoppers,"

- umanned aerial vehicles (UAV),

- microsatellites and nanosatellites,

- scattering of remote sensors (terrestrial, lunar or Mars), and

- many more.

Hastings' Chariots is committed to advancing space

technology with liquid rocket propulsion. Contact us to

see if our products or services can benefit your project.

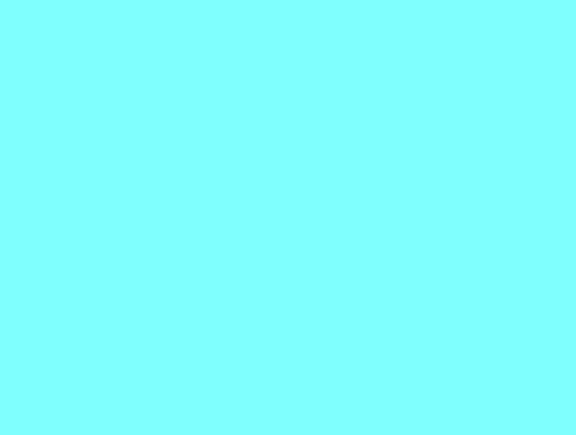

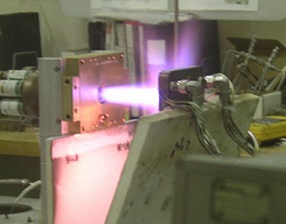

Hastings' Chariots' 1000 pound

thrust liquid rocket engine is

shown on the left being tested on

Hastings' Chariots rocket engine

test stand. The engine is

designed to burn kerosene,

natural gas, biodiesel or

hydrogen. Oxygen, hydrogen

peroxide or nitrous oxide can be

used as the oxidizers.

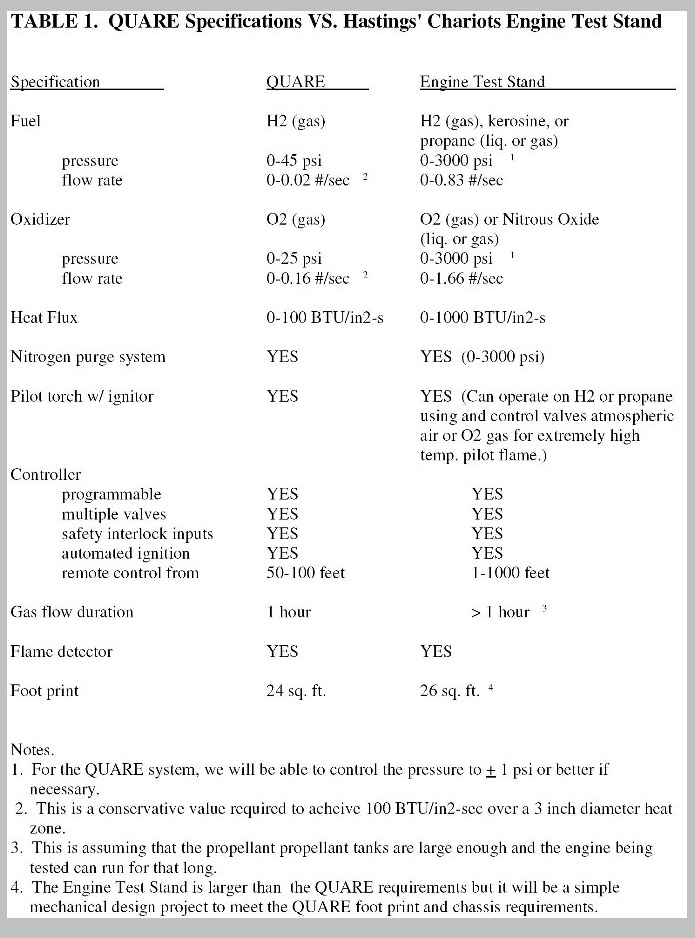

The Quick Access Rocket

Exhaust (QARE) is shown on

the right testing a coupon to

simulate a rocket engine

combustion chamber

environment for materials

testing. The QARE rig (shown

below) was engineered and

manufactured by Hastings'

Chariots for NASA Glenn

Research Center (GRC). The

system is engineered for

hydrogen and oxygen. Photos

courtesy NASA GRC.

Photo courtesy of NASA GRC.

Photo courtesy of NASA

GRC.

The QARE

system can be

configured with

different nozzels

for a variety of

applications as

shown at the

left.

Photo courtesy of NASA

GRC.

Copyright © 2002-2012. All Rights Reserved. Hastings'

Chariots.

T

M